One of the urgent problems of mankind is the purification of the atmosphere from the toxic components of emissions from industrial enterprises.

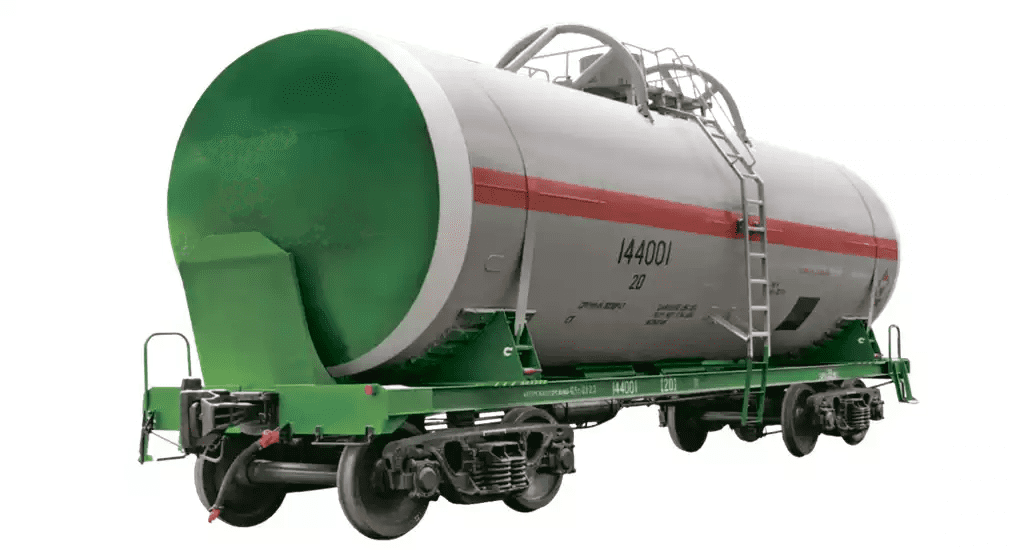

The total amount of harmful emissions into the atmosphere for the year in the republic amounted to 2,271,000 tons per year, and this is no less than 38,000 railway tanks of 60 tons each.

Of these, 134 thousand tons per year, or 2,234 railway tanks of 60 tons each are thrown on the heads of only Almaty residents .

One CHP 2 of Almaty emits 45,000 tons of harmful substances

All these emissions lead to the fact that millions of residents of the republic a year are prone to upper respiratory tract diseases that turn into chronic diseases and lead to premature death.

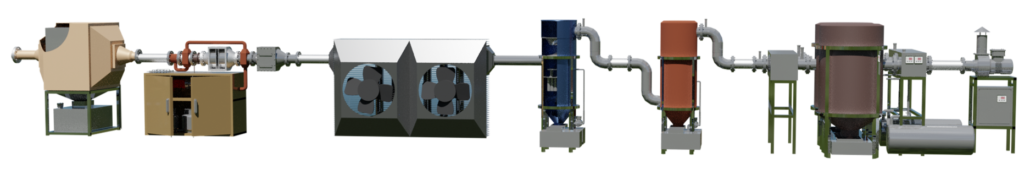

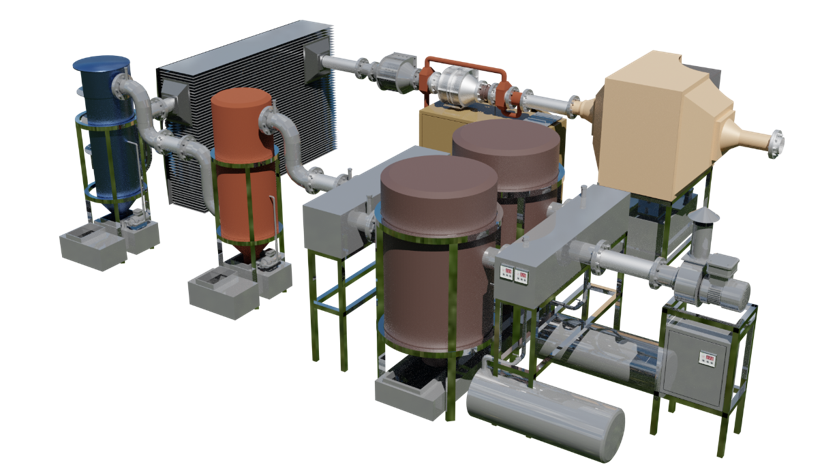

One of the optimal solutions to this problem are the proposed complex cleaning systems.

The integrated treatment systems installed will make it possible to collect all these millions of tons of harmful substances before they are released into the atmosphere, and moreover, to turn them into useful products that generate income and new jobs.

In other words, the installation of the proposed filters will allow toxic components not to be thrown on our heads, but to be turned into useful building material. At the same time, the operation of industrial installations and equipment with a faulty exhaust purification system must be PROHIBITED.

The implementation of this project will make a huge contribution to the normalization of the country’s environmental situation. Accordingly, this will improve the well-being of the population as a whole, which cannot but affect the development of the country.

And in economic terms, the introduction of the proposed technology is the creation of thousands of new jobs, saving tens of trillions of tenge of budgetary funds, the production of millions of tons of useful products from emissions, which, unfortunately, are thrown on our heads today.

Preliminary analysis and testing of ash for strength showed a positive result.

Before the completion of the first stage:

[ycd_countdown id=”404″][/ycd_countdown]This project is carried out as part of the implementation of grant financing for the commercialization of RNNTD, funded by the funds of the State Institution “Science Committee of the Ministry of Education and Science of the Republic of Kazakhstan”

According to the results of the competition for grant financing of projects for the commercialization of the results of scientific and (or) scientific and technical activities for 2022 – 2024 in accordance with the protocol decision of the meeting of the National Scientific Council in the priority direction “Commercialization of RNNTD” Extract No. 1 to the Minutes of the meeting No. 2 dated 09- On November 24, 2022, the project is being implemented by JSC “Institute of Fuel, Catalysis and Electrochemistry named after A.I. D.V. Sokolsky”.