This stage is designed to remove suspended solids and ash from flue gases.

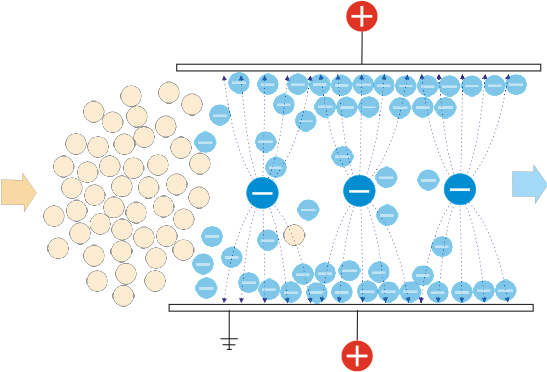

The principle of operation of the electrostatic precipitator is based on the process of deposition of electrically charged dust particles in electric fields. Electric charging of particles occurs in the field of a corona discharge that occurs in an electric field between corona (high-voltage) and collecting (grounded) electrodes.

The process of trapping suspensions in an electrostatic precipitator can be divided into several stages:

• charging of suspended particles;

• the movement of charged particles to the electrodes;

• deposition of charged particles on the electrodes;

• regeneration of electrodes – removal from the surface of the electrodes of the collected particles ;

• removal of collected dust from the bunker part of the electrostatic precipitator.

When selecting an electrostatic precipitator, a calculation is made on the basis of practical data on the permissible speed of the gases being cleaned in the electric field of the electrostatic precipitator. Proceeding from this and from a given flow rate, the area of the working (active) section of the electrostatic precipitators is determined. The design of the electrostatic precipitator is also chosen on the basis of operational experience, based on the condition for ensuring the maximum degree of gas flow purification. According to the required area of the active section and the selected electrostatic precipitator, the required number of electrostatic precipitators is determined.